Steel wire braided rubber hose for mining

APPLICATION: For delivery of water, mineral oil orwaterbased hydraulic oil in the hydraulic system of coalmining machinery and construction machinery andworking temperature range is -40C~ +100C(-40F~+212°F). FEATURE: Made of oil resistant and anti- agingrubber.The reinforcement is braided in black smoothfinish. In coformity with MT/T98-2006.

Classification:

Steel wire braid series

Advice Line:

Description

APPLICATION: For delivery of water, mineral oil orwaterbased hydraulic oil in the hydraulic system of coalmining machinery and construction machinery andworking temperature range is -40C~ +100C(-40F~+212°F).

FEATURE: Made of oil resistant and anti- agingrubber.The reinforcement is braided in black smoothfinish. In coformity with MT/T98-2006.

| TYPE | Metric System Specifications | Inch Specifications | Hose inner diameter 1. | Outer diameter of reinforcement layer W.D | Soft | Tube outside diameter O.D | Max.W.P | p.p | Min.B.P | Min.B.R | WT | |||

| SIZE | SIZE | Min | Max | Min | Max | Min | Max | |||||||

| MM | IN | in | mm | mm | mm | mm | mm | Mpa | Mpa | Mpa | mm | kg/m | ||

| 0601 | 6 | 1/4 | 5.8 | 6.5 | 11.1 | 12.1 | 14.2 | 15.4 | 32 | 40 | 80 | 100 | 0.35 | |

| 0801 | 8 | 5/16 | 7.8 | 8.5 | 13.1 | 14.1 | 16.2 | 17.4 | 28 | 35 | 70 | 115 | 0.43 | |

| 1001 | 10 | 3/8 | 9.8 | 10.5 | 15.1 | 16.1 | 18.1 | 19.3 | 25.6 | 32 | 64 | 130 | 0.49 | |

| 1301 | 12.5 | 1/2 | 12.8 | 13.5 | 18.9 | 19.9 | 21.9 | 23.1 | 22.4 | 33.6 | 56 | 180 | 0.64 | |

| 1601 | 16 | 5/8 | 15.8 | 16.6 | 22 | 230 | 24.7 | 26.3 | 16.8 | 21 | 42 | 205 | 0.75 | |

| 1901 | 19 | 3/4 | 18.8 | 19.8 | 25 | 26 | 27.6 | 29.2 | 14.4 | 18 | 36 | 240 | 0.84 | |

| 2201 | 22 | 7/8 | 21.8 | 22.8 | 28 | 29 | 30.6 | 32.2 | 12.8 | 16 | 32 | 280 | 1 | |

| 2501 | 25 | 1 | 24.8 | 25.8 | 31.5 | 32.5 | 34.2 | 35.8 | 11.2 | 14 | 28 | 300 | 1.1 | |

| 3201 | 31.5 | 1-1/4 | 31.6 | 33.6 | 38.5 | 39.5 | 41.8 | 44.2 | 9 | 11.5 | 22.5 | 420 | 1.4 | |

| 3801 | 38 | 1-1/2 | 37.7 | 39.8 | 45.5 | 46 | 48.8 | 51.2 | 7 | 9 | 17.5 | 500 | 1.58 | |

| 4501 | 25.4 | 1-3/4 | 44.6 | 45.6 | 52.5 | 53 | 54.8 | 57.2 | 5 | 8 | 12.5 | 550 | 1.8 | |

| 5101 | 51 | 2 | 50.7 | 52 | 57.7 | 58.8 | 62.3 | 64.7 | 3 | 6 | 7.5 | 630 | 1.99 | |

| 0602 | 6 | 1/4 | 5.8 | 6.5 | 12.9 | 13.9 | 16 | 17.2 | 56 | 70 | 140 | 100 | 0.48 | |

| 0802 | 8 | 5/16 | 7.8 | 8.5 | 14.9 | 15.9 | 18 | 19.2 | 48 | 60 | 120 | 115 | 0.6 | |

| 1002 | 10 | 3/8 | 9.8 | 10.5 | 16.9 | 17.9 | 19.9 | 21.1 | 40 | 50 | 100 | 130 | 0.68 | |

| 1302 | 12.5 | 172 | 12.8 | 13.5 | 20.7 | 21.7 | 23.7 | 24.9 | 36 | 45 | 90 | 180 | 0.93 | |

| 1602 | 16 | 5/8 | 15.8 | 16.6 | 23.7 | 24.7 | 26.5 | 28.1 | 32 | 40 | 80 | 205 | 1.07 | |

| 1902 | 19 | 3/4 | 18.8 | 19.8 | 26.7 | 27.7 | 29.4 | 31 | 25 | 31.5 | 62 | 240 | 1.08 | |

| 2202 | 22 | 7/8 | 21.8 | 22.8 | 30.7 | 31 | 32.6 | 34 | 22 | 27.5 | 55 | 280 | 1.28 | |

| 2502 | 25 | 1 | 24.8 | 25.8 | 33.5 | 34.5 | 36 | 37.6 | 21 | 26.5 | 52 | 300 | 1.52 | |

| 3202 | 31.5 | 1-1/4 | 31.6 | 33.6 | 40.2 | 41.2 | 43.8 | 46.2 | 17 | 21.5 | 42.5 | 420 | 1.91 | |

| 3802 | 38 | 1-1/2 | 37.7 | 39.8 | 46.5 | 47.5 | 49.8 | 52.2 | 12 | 15 | 30 | 500 | 2.1 | |

| 4502 | 25.4 | 1-3/4 | 44.6 | 45.6 | 53.5 | 54.5 | 56.8 | 59.2 | 9 | 13.5 | 22.5 | 55 | 2.4 | |

| 5102 | 51 | 2 | 50.7 | 52 | 59.5 | 60.5 | 62.8 | 65.2 | 8 | 12 | 20 | 630 | 2.51 | |

| 0803 | 8 | 5/16 | 7.8 | 8.5 | 16.5 | 17.5 | 19.6 | 20.8 | 50 | 75 | 125 | 115 | 0.79 | |

| 1003 | 10 | 3/8 | 9.8 | 10.5 | 18.5 | 19.5 | 21.5 | 22.7 | 45 | 62.5 | 112.5 | 130 | 0.9 | |

| 1303 | 12.5 | 1/2 | 12.8 | 13.5 | 22.5 | 23.5 | 25.5 | 26.7 | 40 | 56 | 100 | 180 | 1.2 | |

| 1603 | 16 | 5/8 | 15.8 | 16.6 | 25.5 | 26.5 | 28.3 | 29.9 | 35 | 43.5 | 87.5 | 205 | 1.39 | |

| 1903 | 19 | 3/4 | 18.8 | 19.8 | 28.5 | 29.5 | 31.2 | 32.8 | 28 | 35 | 70.5 | 240 | 1.54 | |

| 2203 | 22 | 7/8 | 21.8 | 22.8 | 31.5 | 32.5 | 34.2 | 35.8 | 25 | 31.5 | 62.5 | 280 | 1.66 | |

| 2503 | 25 | 1 | 24.8 | 25.8 | 34.6 | 35.6 | 37.2 | 38.8 | 24 | 30 | 60.5 | 300 | 1.97 | |

| 3203 | 31.5 | 1-1/4 | 31.6 | 33.6 | 42 | 43 | 45.8 | 48.2 | 19 | 24 | 47.5 | 420 | 2.48 | |

| 3803 | 38 | 1-1/2 | 37.7 | 39.8 | 48 | 49 | 51.8 | 54.2 | 15 | 19 | 37.5 | 500 | 2.9 | |

Keywords:

Steel wire braided rubber hose for mining

Related

Embedded steel wire hydraulic suction hose

CONSTRUCTION: this hose shall consist of on innertubeof oil resistant synthetic rubber layer, areinforcement consist of a ply or plies of woven orbraided textile fibers with a suitable spiral of steelwire, and an oiland weather resistant synthetic rubbercover. APPLICATION: this section covers hose for use in lowpressure and vacuum applications with petroleumbase hydraulic fluids within a temperature of-40°C~+100°C(-40°F~+212°F).

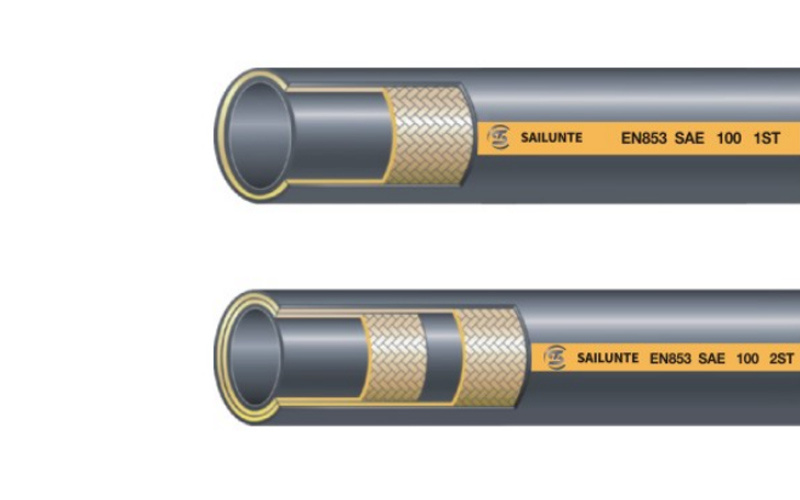

DetailsSteel wire braided rubber hose

APPLICATION: For delivery of hydraulic resistantliquids or water-based liquids. FEATURE: Made of oil-resistant and anti-agingrubber. The reinforcement is smooth finish. Inconformity with DIN EN853 1ST and 2ST standardSAE J517100R1A and 100R2A .Working temperaturerang:-4(TC~+100°C(-40。F~+212°F).

DetailsMessage